Novo Nordisk and Eli Lilly have struck gold. After decades of research, their GLP-1 obesity drugs appear to really work.

Globally, at least 1.9 billion people are overweight, and J.P. Morgan estimates that—in the U.S. alone—about 30 million people will soon be taking weight loss drugs: Wegovy from Novo Nordisk and ZepBound from Eli Lilly. Novo Nordisk’s market capitalization ($442B) is already larger than the GDP of Denmark ($404B), the country where the company is headquartered. The market for semaglutide-based products is projected to swell to $71B in less than a decade.

Stifel, the investment banking firm, has argued that the total market opportunity could be an order of magnitude larger. If that prediction bears fruit, it would mean that a biologically-produced molecule would, for the first time in history, outsell the iPhone.

All of this future value, of course, relies upon these companies actually making enough of their product to meet the growing demand.

So far, they haven’t been able to do that. In November, Novo Nordisk invested $6B in additional production capacity. “With the capacity we’re building and what competition is building, I believe we are far from getting to a billion people,” Lars Fruergaard Jørgensen, the company’s CEO, told reporters. “I believe we will continuously have to invest.”

The story has been no different for Lilly. According to CEO David Ricks, they will need to invest in further manufacturing capacity “at risk,” meaning they need to build even faster than the market grows in order to meet future demand.

All of this should make synthetic biologists salivate. Biomanufacturing—making things with biology—is a cornerstone of the discipline. For many, the North Star of the field is to be able to “grow anything” using the tools of biotechnology. Here, “anything” really means anything; scientists and writers have long imagined homes that grow from planted seeds or clothes that materialize from clusters of cells. This type of vision stems from the observation that “Atoms are Local”: living systems are capable of self-assembling and growing on every corner of the planet using only resources that are locally available.

But where the rubber meets the road, synthetic biology doesn’t yet have a solution to offer Novo or Lilly. In the first real test of delivering a complex biomolecule to over a billion people, little has changed from how Genentech first approached manufacturing in the 1980s; Cells are genetically engineered and then grown in steel tanks. In the case of semaglutide, those cells are Saccharomyces cerevisiae—also known as Baker’s yeast—engineered to secrete a peptide precursor that is later purified, chemically modified, packaged into an injectable or tablet form, and then shipped around the world. Continuing this method may not scale. So, what are the possible paths forward from here?

One approach is to do more of the same but better. Companies are already becoming more efficient at fermentation, the process by which organisms consume sugars (typically glucose) and use enzymes to convert them into valuable chemicals, such as semaglutide. A 2019 report from RethinkX, an independent research group, states that the “cost to produce a single molecule using [precision fermentation] has fallen from $1 million per kilogram in 2000, to about $100 today.” Efforts are also underway at Asimov and elsewhere to make cells more efficient units of production. Several companies, including Cytiva and Pow.bio, are working to make cheaper and more efficient bioreactors.

But a more radical direction is to venture away from cell-based biomanufacturing entirely. This is the true kernel of the Atoms are Local philosophy. “The leaves on a tree don’t come from a factory and then get shipped to where the tree is going to be and taped and stapled to the twigs and branches,” says Drew Endy, professor of bioengineering at Stanford University. “The photons and molecules arrive where the biology is going to grow and the biology grows locally.”

Why, then, have we chosen to build expensive centralized factories with steel tanks as our primary mode of bioproduction? The total global bioprocessing capacity was estimated at 17.4 million liters in 2021, according to an analysis by BioProcess International. We further estimate that supplying just the U.S. market with Wegovy will, by 2030, require about one million liters of production capacity. It’s time to consider other potential scales for biomanufacturing, both below and above the level of the cell.

Making with Molecules

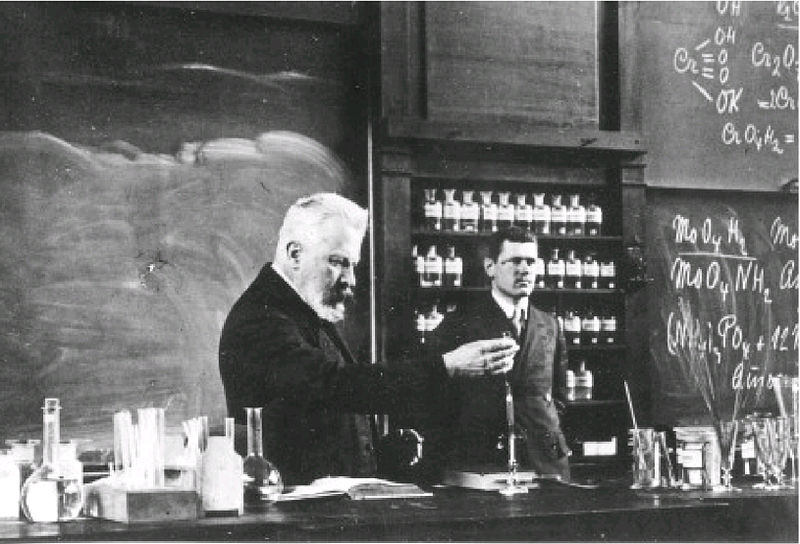

Throughout the 1800s, many biologists believed in vitalism, the notion that living organisms are “alive” because they possess a spark or force, reminiscent of the soul. Supporting their claim, these biologists noted that living yeast cells could transform sugar into alcohol; a feat that seemed impossible by purely chemical means. But then, a German chemist named Eduard Buchner dealt a blow to vitalism in 1897, when he demonstrated that enzymes alone could do the same.

To demonstrate this, Buchner grew yeast cells in a flask, poured them into a mortar, and mixed the cells with quartz and kieselguhr, a rock that had been pulverized into white powder. Buchner then crushed up the yeast cells with a pestle and pressed the concoction through a strainer to make a “juice,” or cell-free extract. After confirming that this extract was completely devoid of living cells, Buchner added a bit of sugar to the liquid and found that alcohol was produced. Buchner earned the 1907 Nobel Prize in Chemistry for this experiment.

His key insight hinged upon the fact that living cells are essentially bags of liquid filled with enzymes, or proteins that speed up chemical reactions. Water accounts for 70 percent of a bacterium by mass; the other 30 percent includes everything else: proteins, RNA, DNA, lipids, and so on. A cell-free extract, then, is what happens when one strips away cell walls and membranes and collects only the molecules inside. Without cell membranes—without “life”—it is far easier to focus on the molecules within; the biochemistry. For this reason, cell-free extracts offer distinct advantages over living cells for biomanufacturing.

In living cells, metabolism is tightly linked to cellular growth, which often makes it difficult to coax cells into making high quantities of a single product. A large part of a cell’s energy and resources go towards growth and maintenance, but these energy requirements are eliminated in a cell-free environment; a higher fraction of enzymes can be redirected toward making a specific drug, such as semaglutide.

Cell-free extracts—made from microbes, insects, or even animal cells—are also inherently malleable. When scientists engineer metabolic pathways within a living cell, a single misstep (such as a genetic mutation) can kill everything. But this isn’t a problem with extracts. By stripping enzymes from their original vessels, it’s far simpler to adjust and tune the concentration of each component to find an “ideal” mixture to produce the maximum amount of a chemical product.

Solugen, a biotechnology company in Houston, already uses artificial intelligence to engineer enzymes that can convert renewable feedstocks, such as corn syrup, into molecules with yields up to 90 percent. Their process requires minimal heat or energy and produces zero emissions. The company’s “Bioforge” facility can make 10,000 metric tons of chemicals per year with just 20,000 square feet of space, according to reporting by CNBC. It’s cell-free biology at scale.

Scaling biomanufacturing capacity doesn’t necessarily hinge on more Bioforges, though. Another option is to use a cell’s enzymes to make molecules and medicines on-demand, even in resource-starved settings that lack access to a “cold chain” where medicines can be stored with refrigeration.

MenAfriVac is a meningococcal vaccine that remains active, without refrigeration, for up to four days and has significantly boosted vaccine coverage in parts of sub-Saharan Africa. But cell-free extracts can go much further. Once mixed with maltodextrin, a sugar polymer, extracts can be freeze-dried and then stored for up to four weeks at room temperature. Mixing the extracts with a bit of water and genetic material then “reboots” the enzymes, which make conjugate vaccines at a cost of about $0.50 per dose.

An alternative approach is to make molecules not in tubes, vials, or cells, but inside the body itself. This was the founding ethos of Moderna, the mRNA vaccine developer, when it was launched in 2010 by Noubar Afeyan and Doug Cole at Flagship Pioneering.

Shortly after the company was founded, Afeyan called up Stéphane Bancel, the CEO of a French diagnostics company, and asked him to stop by his office at Flagship so that he could share his vision for a revelatory medicine-making factory.

“It was about 6 p.m. by the time Bancel made it over to Flagship, where Afeyan delivered his pitch: He wanted Bancel to work on a startup that had so far hired only a single staff scientist and conducted just one mouse trial. Nevertheless, he told Bancel, the stakes were extremely high. If the technology proved successful in human beings, it would take Moderna weeks, not years, to make a new product,” wrote Catherine Elton in Boston Magazine.

“And there was more: Because the company would always be making the same thing—mRNA—the only thing that would ever have to change was the protein for which the mRNA would be coded. That meant that the company could make all of its products in the same plant—and that plant would cost a tenth of a typical one.”

The origin of Moderna, in other words, was to find a way to instruct “cells to manufacture drugs on demand.” Even today, the company’s profile on the Flagship Pioneering website knocks the size of “pharmaceutical factories,” which “can run to 800,000 square feet or more,” and touts the beauty of cells as factories, with messenger RNA as their “foreman.” Although the company’s initial aim was to coax the body to make all kinds of different drugs using small amounts of mRNA, their shift to vaccines during the pandemic offered lower-hanging fruit.

When mRNA vaccines are injected into the body, they take over host cell protein machinery and coax them to produce an antigen, which, in turn, trains the immune system to make antibodies and neutralize a pathogen. A small message, encoded in a limited amount of genetic material, is thus amplified throughout the body.

Moderna administered nearly 150 million doses of their COVID-19 vaccine in one year, according to Our World in Data. And given that RNA and lipid nanoparticle synthesis is highly efficient compared to typical bioproduction, it’s likely that the company could have scaled to billions of doses.

Both cell-free extracts and mRNA offer promising evidence that biomanufacturing can scale outside the confines of steel tanks. But there is another path forward: one that involves exploiting plants, microbes, and other biological lifeforms out in the “real world.” A farmer who harvests corn typically leaves the stalks and stems in the field, which amounts to hundreds of millions of tons of wasted biomass from corn alone each year. One could imagine entire fields of corn and soybeans that still produce food, but whose stalks double as biosynthesis vessels for vaccines or medicines.

Molecular Farming

Drew Endy looks at the world around him a little bit differently than most. Take pine cones, for example. One day, he realized that his yard was littered with these dense, cylindrical objects. Tracking down waste estimates from his California neighborhood with 32,000 residents, he determined that each year roughly 500 pounds of garden clippings are disposed of per person.

But to Endy, that isn’t waste. It is “sixteen million pounds of matter compiled from the atmosphere!” Biology compiles matter with atomic precision on every corner of the planet. We just haven’t figured out how to effectively harness this latent manufacturing capacity.

The implication here is that evolved organisms are more efficient at physical manufacturing than any man-made process invented to date.

Consider food production. Agriculture, the cultivation of plants and animals, is how we meet the world’s caloric needs. It’s the bedrock of modern civilization. The same is true for energy. Unfortunately, ripping the decayed remains of this planet’s first life forms out of the ground, ”fossil fuel,” is still the most cost-efficient source of energy. We cut down more than 40 million trees per day for building materials and fuel.

But when it comes to the production of recombinant proteins like GLP-1 drugs, we don’t harness the full power of bioproduction at scale. We stick to microbes in steel tanks. Still, we cannot entirely attribute this fact to a lack of interest or effort. Experiments around using genetically modified organisms to produce proteins have been taking place since the earliest days of the recombinant DNA revolution.

As early as the 1980s, researchers investigated producing antibodies and human blood proteins in tobacco plants. A Nature Biotechnology paper in 1990 noted that “plants may be a suitable alternative for microbial expression systems, as the production of plant biomass is inexpensive. This aspect becomes increasingly important in cases where large amounts of protein need to be produced.”

At the turn of the century, hundreds of companies were manufacturing recombinant proteins in plants. The vision of the future was bright: “Imagine a world in which any protein, either naturally occurring or designed by man, could be produced safely, inexpensively, and in almost unlimited quantities using only simple nutrients, water, and sunlight.”

Progress was rapid until it wasn’t. In 2002, Prodigene, one of the leading “molecular farming” companies, encountered a major setback. The company harvested a diagnostic protein from genetically modified corn at its site in Nebraska. When the field was replanted with soybeans, though, some of the corn kernels contaminated the new crop.

Fear of “drugs in your cornflakes” sparked major pushback. Prodigene was fined and had to pay $3M in compensation for the wasted soybean crop, but that was only a fraction of the true cost. In response to this hysteria, regulation was aggressively tightened. To make matters worse, many companies struggled with engineering problems on the path to scale.

Between the technical uncertainty and the horrendous PR, pharmaceutical companies had little interest in adopting molecular farming technologies. Once approved, patent-protected drugs are the highest-margin physical products on the planet—even with the high price of bioreactors. The real cost is clinical development. It follows that these companies, then, are not incentivized to radically transform biomanufacturing. Why rock the boat? No process engineer gets fired for fermenting cells in steel tanks.

With this trifecta of hurdles—technical, regulatory, market—the field of molecular farming effectively “imploded.”

But despite the chilling in the field, true believers pushed forward. In 2012, an Israeli company called Protalix gained approval for their plant-based enzyme product for Gaucher’s disease. In 2016, a company called Synageva BioPharma (formerly AviGenics) was acquired by Alexion for $8.4B. Kanuma, their FDA-approved protein product for rare lysosomal diseases, is “purified from the egg white of transgenic hens.” Finally, “pharmed” drugs are making their way onto the market.

The technology only continues to improve. When Kanuma was first developed, recombinant expression in hens was tricky and had relatively low yields. The primary motivation for production in egg whites was the ease of certain chemical modifications. Proteins were produced with yields at the microgram scale. Now, with CRISPR technology, researchers have demonstrated the production of milligrams of monoclonal antibodies from egg whites, a three orders of magnitude improvement.

Think about that. A dozen eggs—costing roughly $1 to produce—could yield a gram of monoclonal antibodies. How many egg-producing farms would it take to produce the U.S. supply of GLP-1 drugs? The rough math suggests there is demand for around 3 million grams of the drug. Egg-laying hens produce 300 eggs a year on average. So if we’d need roughly 100,000 hens, and industrial egg farms in the United States can house up to a million hens, the answer is less than one. For context, the United States produced 92.6 billion eggs in 2022 alone.1

This is the enormous potential scale advantage of molecular farming.

New startups aim to capitalize on this opportunity. Future Fields is working to produce reagents and proteins scalably and sustainably by harnessing fruit flies as miniature bio-factories. Tiamat Sciences harvests a variety of protein products in tobacco plants. Cirsium Bio is using plants to produce viral vectors for gene therapy. BioDrive aims to produce abundant supplies of orally available biologics by growing them in edible crops.2 Bear in mind that because the landscape of companies pursuing molecular farming is beginning to swell again, these are illustrative examples rather than a map of the whole territory.

Biological research and technology development is a continual lesson in humility. Cells are complex adaptive systems that evade simple descriptions. Our best tools for manipulating genes—like CRISPR gene editing—are discovered rather than invented. Even after decades of sustained process development for fermentation, it may well be the case that organisms are still the most efficient bioreactors on the planet.

Exploring New Scales

Perhaps synthetic biology has largely remained sealed off inside steel tanks in closely monitored labs because it scares people. After all, the notion of using synthetic mRNA molecules to program our bodies to produce drugs is new and unfamiliar, as is the idea that we could program plants, insects, and animals to produce engineered proteins. Cells feelmore containable than fields full of transgenic organisms. It seems like people shouldn’t be programming trees in their backyard or plants in their garden to synthesize designs for bioproducts that they download from the Internet.

For biotechnologists, part of our duty is to address this fear. We need to help people imagine a future with ubiquitous biotechnology that is worth living in. In 2020, the total amount of human-made mass exceeded global biomass for the first time. This has enormous implications for planetary and ecosystem health. However, if we could more effectively exploit existing biomass through biomanufacturing, we could lessen the toll of degrading the world’s natural resources. After all, a true global bioeconomy would enable us to make whatever we need, wherever we need it.

Ultimately, the GLP-1 shortage is a canary in the coal mine—it is one drug, for one patient population. And while employing all of these prospective approaches should help meet the demand for new medicines such as Wegovy and ZepBound, it is still a far cry from the promise of growing anything. Arriving at a future where this is possible will require us to expand the scope of our biomanufacturing strategies to include distributed cell-free technologies, more efficient fermentation infrastructure, and more radical molecular farming solutions—a vision that moves us beyond steel tanks.

***

Niko McCarty is a founding editor at Asimov Press.

Elliot Hershberg is a PhD student at Stanford University. He writes Century of Biology and is an investor at Not Boring Capital.

Cite: Niko McCarty & Elliot Hershberg. “Beyond Steel Tanks.” Asimov Press (2024). DOI: https://doi.org/10.62211/72po-11rs

Footnotes

- It is worth noting that this opportunity comes with unignorable ethical challenges due to the inhumane conditions characteristic of the industrial egg-production industry. Even setting aside the diswelfare produced by battery-cages, around 6-7 billion male chicks are culled each year because they produce no economic value in this supply chain. We’d like to thank Matt Osman who brought this data to our attention, and who is exploring ideas around more ethical animal husbandry.

- Disclosure: Not Boring Capital is an investor in BioDrive.

Always free. No ads. Richly storied.